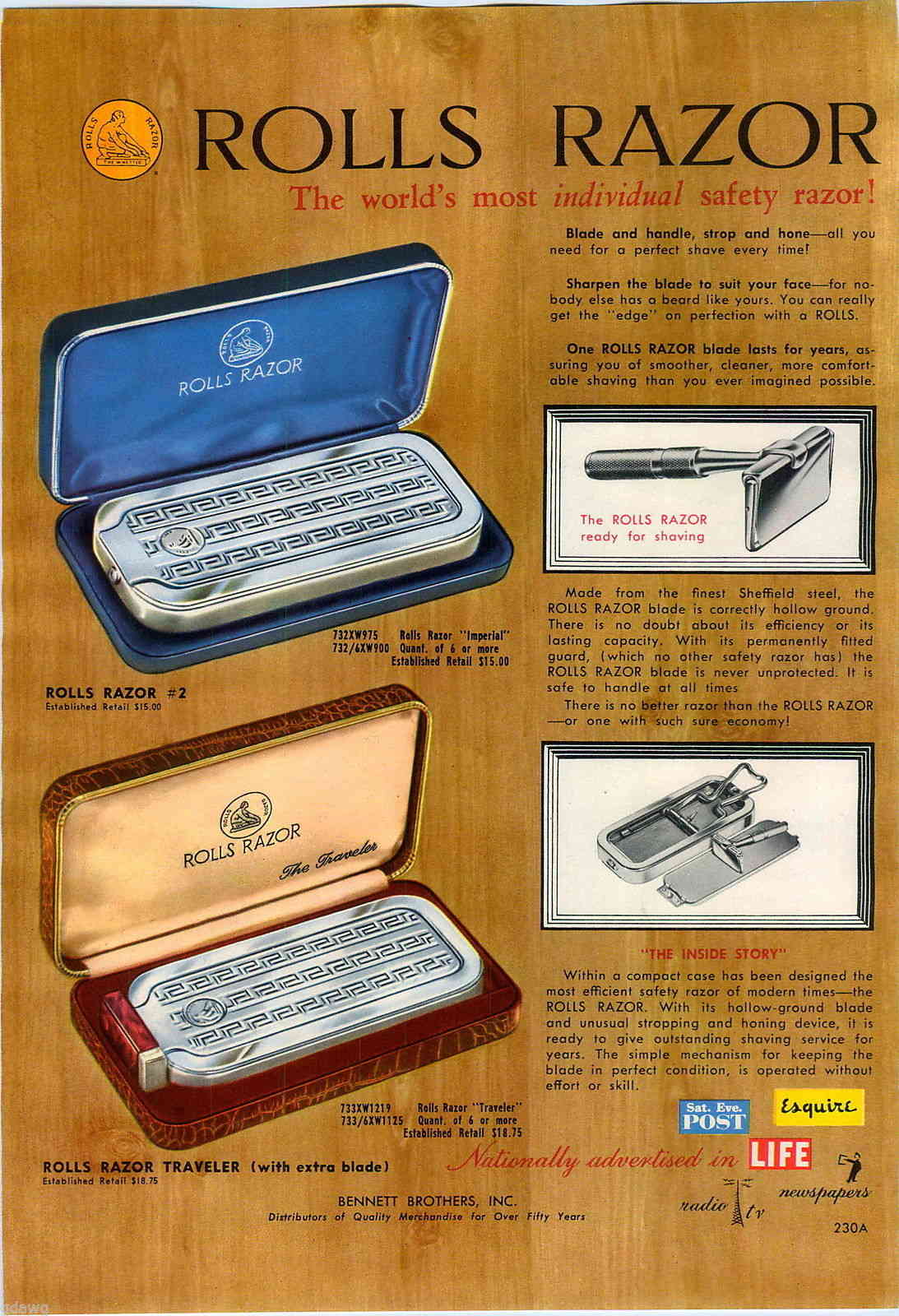

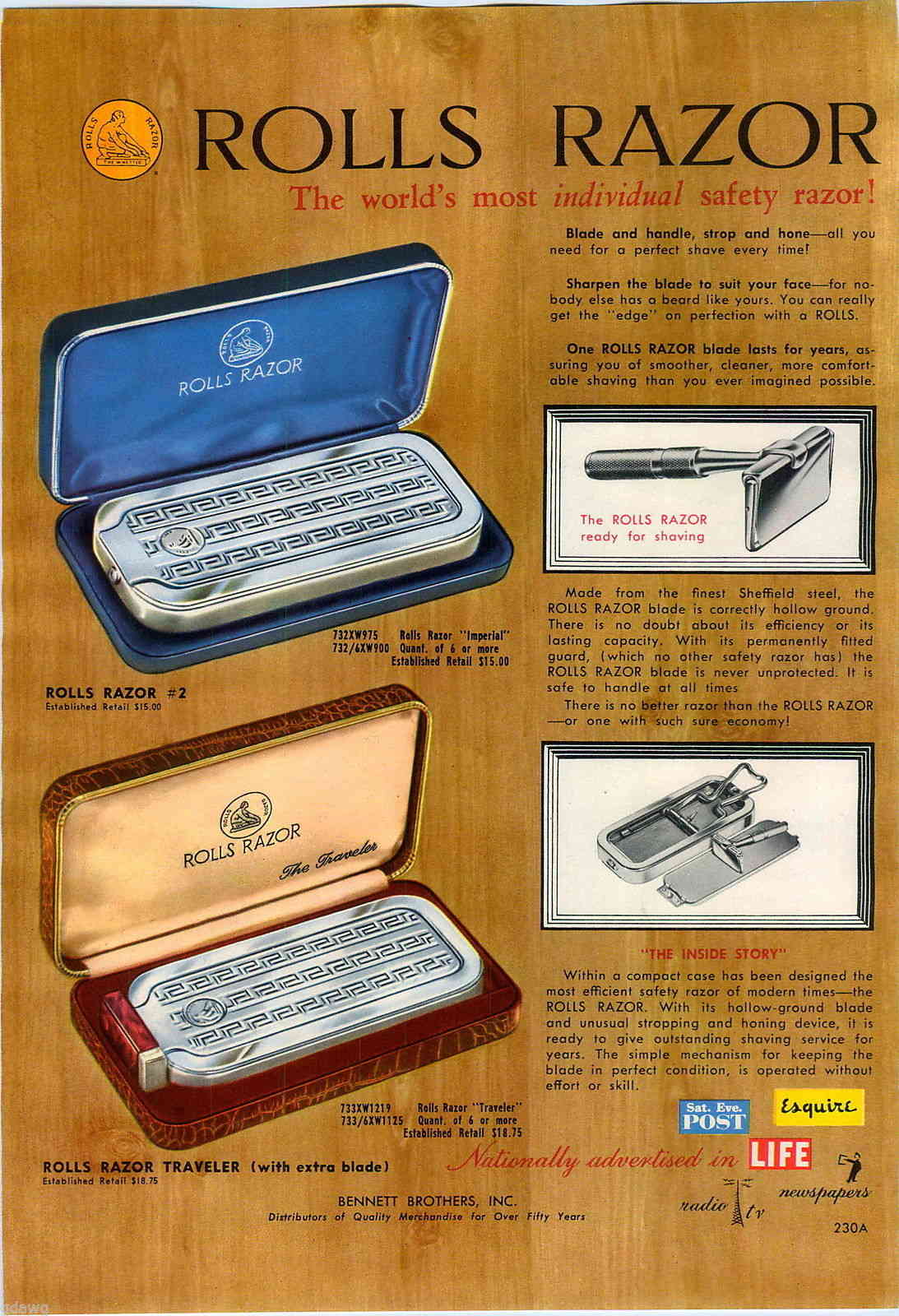

Rolls Razor Imperial N°2

+7

didi.adri

Ancien membre 11

Patka

moas

Chrissss

pitoufo

gigabillou

11 participants

Page 1 sur 2 • 1, 2

gigabillouPilier

gigabillouPilier

- Messages : 11083

Date d'inscription : 17/07/2013

Age : 60

Rolls Razor Imperial N°2

Rolls Razor Imperial N°2

Jeu 19 Juin 2014, 17:53

Salut les gars,

Bah voila tien, tout ca a cause de Loïc qui nous montre des choses magnifique

Bon dieu c'est lourd

L'ensemble fait 470g

Il est quasi NOS, la lame est encore dans son enveloppe huilée, le cuir et la pierre on encore leur papier sulfurisé et sont neufs, le mécanisme fonctionne a merveille, content le Billou

Les deux taches sur la pierre sont des taches de gras de la lame, j'essayerais de les faire partir avec de l'alcool isopropylique

Une vidéo explicative sur la méthode d'affilage

Bah voila tien, tout ca a cause de Loïc qui nous montre des choses magnifique

Bon dieu c'est lourd

L'ensemble fait 470g

Il est quasi NOS, la lame est encore dans son enveloppe huilée, le cuir et la pierre on encore leur papier sulfurisé et sont neufs, le mécanisme fonctionne a merveille, content le Billou

Les deux taches sur la pierre sont des taches de gras de la lame, j'essayerais de les faire partir avec de l'alcool isopropylique

Une vidéo explicative sur la méthode d'affilage

pitoufoRéférent

pitoufoRéférent

- Messages : 1580

Date d'inscription : 30/09/2013

Age : 49

Localisation : Madrid-Espagne

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Jeu 19 Juin 2014, 18:25

Pas bien compris le fonctionnement...c'est le rasoir qui se visse pour être ajusté et affûter sur la pâte du couvercle ?

gigabillouPilier

gigabillouPilier

- Messages : 11083

Date d'inscription : 17/07/2013

Age : 60

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Jeu 19 Juin 2014, 18:30

J'ai édité et ajouté une vidéo explicative

ChrissssAdmin

ChrissssAdmin

- Messages : 20485

Date d'inscription : 12/11/2011

Age : 49

Localisation : Aubange, Belgique

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Jeu 19 Juin 2014, 18:37

Joli, je suis curieux de lire ton retour d'expérience

pitoufoRéférent

pitoufoRéférent

- Messages : 1580

Date d'inscription : 30/09/2013

Age : 49

Localisation : Madrid-Espagne

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Jeu 19 Juin 2014, 18:46

Hooooooooo m'en faut un !

moasBoss

moasBoss

- Messages : 3406

Date d'inscription : 10/07/2012

Age : 38

Localisation : Belgique

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Jeu 19 Juin 2014, 18:51

joli, mais faut certainement faire attention à l'usage

gigabillouPilier

gigabillouPilier

- Messages : 11083

Date d'inscription : 17/07/2013

Age : 60

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Jeu 19 Juin 2014, 21:38

J'ai dégraissé la lame et fait un essai sur le bras, ca accroche grave

Du coup, j'ai passé une bonne 40 ene de fois sur le cuir, c'est super simple d'utilisation, ca le fait tout seul

test... et la ca coupe a la volée, ca tranche sans rien sentir, c'est super doux

ca coupe a la volée, ca tranche sans rien sentir, c'est super doux

J'essaierai de tester avant de partir en vacance, par contre ca va pas être simple, je part demain soir

Du coup, j'ai passé une bonne 40 ene de fois sur le cuir, c'est super simple d'utilisation, ca le fait tout seul

test... et la

J'essaierai de tester avant de partir en vacance, par contre ca va pas être simple, je part demain soir

PatkaRéférent

PatkaRéférent

- Messages : 2038

Date d'inscription : 13/10/2012

Age : 67

Localisation : Bretagne

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Jeu 19 Juin 2014, 22:00

Tu vas pas te raser en vacances ?

gigabillouPilier

gigabillouPilier

- Messages : 11083

Date d'inscription : 17/07/2013

Age : 60

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Jeu 19 Juin 2014, 22:10

Je vais me limiter pour les vacances, ne prendre que deux ou trois DE, autant de savons et un ou deux blaireaux, je ne prendrai pas ce type de rasoir par contre

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Jeu 19 Juin 2014, 22:25

quoi !?? pour les vacances tu ne prends que ca ? meme pas 4 ou 5 AS et deux ou trois baumes?

quoi !?? pour les vacances tu ne prends que ca ? meme pas 4 ou 5 AS et deux ou trois baumes?

gigabillouPilier

gigabillouPilier

- Messages : 11083

Date d'inscription : 17/07/2013

Age : 60

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Jeu 19 Juin 2014, 22:30

Bah si, quelques AS quand même

didi.adriRéférent

didi.adriRéférent

- Messages : 2036

Date d'inscription : 26/02/2012

Age : 43

Localisation : Le coeur dans le Lot

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Jeu 19 Juin 2014, 22:30

Sympa ce rasoir...

On a qu'à faire un sondage pour savoir quel rasoir tu prends en vacances

On a qu'à faire un sondage pour savoir quel rasoir tu prends en vacances

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Jeu 19 Juin 2014, 22:33

j espere que tu as de grandes valises et un grand coffre

gigabillouPilier

gigabillouPilier

- Messages : 11083

Date d'inscription : 17/07/2013

Age : 60

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Ven 20 Juin 2014, 10:36

Oui, j'ai un peu de place dans la voiture

Surpris par la douceur de ce rasoir (faut juste encore un peu de cuir pour être parfait), ca tranche sec, l'exposition de la lame est parfaite, aucun risque de se trancher l'épiderme.

Le manche par contre lui, est très "désagréable" a maintenir, c'est vraiment trop fin et la prise en main est délicate

J'ai eu malgré tout un superbe rasage ce matin, j'imagine une fois bien affilé

A posséder absolument pour qui veut tester ce type de SE

Surpris par la douceur de ce rasoir (faut juste encore un peu de cuir pour être parfait), ca tranche sec, l'exposition de la lame est parfaite, aucun risque de se trancher l'épiderme.

Le manche par contre lui, est très "désagréable" a maintenir, c'est vraiment trop fin et la prise en main est délicate

J'ai eu malgré tout un superbe rasage ce matin, j'imagine une fois bien affilé

A posséder absolument pour qui veut tester ce type de SE

loic-de-niceHomeboy

loic-de-niceHomeboy

- Messages : 1179

Date d'inscription : 19/08/2012

Age : 65

Localisation : Nice, France, Singapore, Singapore, et aussi près de Glam, Sarangani Province , Mindanao Island , Philippines

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Ven 20 Juin 2014, 11:43

gigabillou a écrit:Oui, j'ai un peu de place dans la voiture

Surpris par la douceur de ce rasoir (faut juste encore un peu de cuir pour être parfait), ca tranche sec, l'exposition de la lame est parfaite, aucun risque de se trancher l'épiderme.

Le manche par contre lui, est très "désagréable" a maintenir, c'est vraiment trop fin et la prise en main est délicate

J'ai eu malgré tout un superbe rasage ce matin, j'imagine une fois bien affilé

A posséder absolument pour qui veut tester ce type de SE

Copieur !

graisse de phoque uniquement pour le cuir et eau pour la pierre et bien sur retourner la lame à chaque rasage

gigabillouPilier

gigabillouPilier

- Messages : 11083

Date d'inscription : 17/07/2013

Age : 60

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Ven 20 Juin 2014, 12:02

Merci des conseils Loïc

Il est extra ce rasoir, je n'aurais jamais imaginé me raser un jour, avec ce type de SE

Il est extra ce rasoir, je n'aurais jamais imaginé me raser un jour, avec ce type de SE

InvitéInvité

InvitéInvité

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Ven 20 Juin 2014, 12:49

gigabillou a écrit:Merci des conseils Loïc

Il est extra ce rasoir, je n'aurais jamais imaginé me raser un jour, avec ce type de SE

J'adore le concept, j'adorerais expérimenter ce genre de rasoir.

Si ce n'est pas indiscret, combien ça vaut ce genre de bestiolle et très bon état ?

gigabillouPilier

gigabillouPilier

- Messages : 11083

Date d'inscription : 17/07/2013

Age : 60

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Ven 20 Juin 2014, 12:56

Dans le même état que j'ai eu, une 40 ene d'€

Faut faire attention a la pierre, elle est souvent cassée, et surtout avoir une lame neuve !

Ca pullule sur les Bay en général

Faut faire attention a la pierre, elle est souvent cassée, et surtout avoir une lame neuve !

Ca pullule sur les Bay en général

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Lun 23 Juin 2014, 14:37

gigabillou a écrit:

Faut faire attention a la pierre, elle est souvent cassée, et surtout avoir une lame neuve !

Ca pullule sur les Bay en général

ça pulule, oui, mais avec les lames neuves, un peu moins. Faites gaffe

loic-de-niceHomeboy

loic-de-niceHomeboy

- Messages : 1179

Date d'inscription : 19/08/2012

Age : 65

Localisation : Nice, France, Singapore, Singapore, et aussi près de Glam, Sarangani Province , Mindanao Island , Philippines

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Lun 23 Juin 2014, 21:28

[quote="Cha-wing!!"]

ça pulule, oui, mais avec les lames neuves, un peu moins. Faites gaffe [/quote

[/quote

En effet faut faire gaffe comme tu dis et prendre le temps d'en trouver un neuf et surtout ne pas hésiter à monter en gamme, les modèles comme le traveller et autres welther outre l'étui alligator viennent avec deux à 4 lames neuves et la pate pour le stropper

..... et à la moindre trace de rouille de vert de gris et autres fantaisies sur quelque partie de l'objet que ce soit ou marque sur la pierre ou le cuir : fuir .....

Chez Rolls razors seule la toute première qualité est digne d'achat , n’oubliez pas que si ce n'est pas le cas votre set vous ne pourrez PAS le revendre si vous n'en vouliez plus c'est aussi simple que ça .... rien qu'en ligne plus de 1000 sont proposés sur la baie chaque année ....95% ne valent RIEN

J'ai une amie chasseuse de longue date pour moi en Angleterre que j'ai chargée d'en trouver deux puis maintenant trois en parfait état à prix décent (ce que j'appelle moi un très bon rapport qualité prix ....

celui de giga est un modèle d'entrée de gamme pas bien cher mais ça ne correspond pas du tout à ma définition de parfait état même si cela lui convient ....au vu précisément de l'état je me serais abstenu.... pas de lames neuves parfaitement conservées ou présence de la moindre tache ou trace d'oxydation ou que ce soit = une seule règle : ne pas acheter .... simple mais redoutablement efficace .... ebay ? oubliez ! la perfection vous couterait un bras et 95% de ce que vous y verrez ne vaudra pas le prix payé allez plutôt passer un week end prolongé à Londres ou Glasgow ce sera plus fun et vous trouverez probablement l'un des modèles de la gamme neuf ou presque .... en prime avec le sourire de la vendeuse ... si vous avez de la chance vous trouverez aussi des kits de remplacement..... (lames cuirs pierres pate stropper pour VOTRE MODELE ....les pots de pate ? = impossible à fabriquer (j'ai essayé et pourtant je suis assez bon sur ce point ... la pate Rolls , ça ne s'imite pas !)

Je l'ai déjà dit : quand je poste un objet dans la rubrique revue ne vous précipitez pas sur le marché pour trouver la même chose , pour deux raisons , souvent je présente un modèle "showcase" et trouver celui là m'a parfois pris 10 ans.... alors est ce trouvable à qualité égale ? oui mais généralement pas sur la baie ..... et secondo, je poste les mêmes revues sur des listes de diffusion en anglais allemand et italien et si tout le monde cherche la même chose en même temps vous ferez grimper les prix ....pas la qualité de ce que vous achèterez....

Ceux qui voudraient un rolls de moyen à haut de gamme neuf ou très approchant, (je pense que tout le monde connait mes exigences qualité , mettez vous en file d'attente .... depuis ce soir celle çi a déja trois numéros ...... la patience est une vertu en matière de collection (et même si ce n'est que pour vous raser ....)

Attention les pièces d'un modèle donné ont spécifiques et ne vont généralement pas sur les autres .....!!!

gigabillou a écrit:

Faut faire attention a la pierre, elle est souvent cassée, et surtout avoir une lame neuve !

Ca pullule sur les Bay en général

ça pulule, oui, mais avec les lames neuves, un peu moins. Faites gaffe

En effet faut faire gaffe comme tu dis et prendre le temps d'en trouver un neuf et surtout ne pas hésiter à monter en gamme, les modèles comme le traveller et autres welther outre l'étui alligator viennent avec deux à 4 lames neuves et la pate pour le stropper

..... et à la moindre trace de rouille de vert de gris et autres fantaisies sur quelque partie de l'objet que ce soit ou marque sur la pierre ou le cuir : fuir .....

Chez Rolls razors seule la toute première qualité est digne d'achat , n’oubliez pas que si ce n'est pas le cas votre set vous ne pourrez PAS le revendre si vous n'en vouliez plus c'est aussi simple que ça .... rien qu'en ligne plus de 1000 sont proposés sur la baie chaque année ....95% ne valent RIEN

J'ai une amie chasseuse de longue date pour moi en Angleterre que j'ai chargée d'en trouver deux puis maintenant trois en parfait état à prix décent (ce que j'appelle moi un très bon rapport qualité prix ....

celui de giga est un modèle d'entrée de gamme pas bien cher mais ça ne correspond pas du tout à ma définition de parfait état même si cela lui convient ....au vu précisément de l'état je me serais abstenu.... pas de lames neuves parfaitement conservées ou présence de la moindre tache ou trace d'oxydation ou que ce soit = une seule règle : ne pas acheter .... simple mais redoutablement efficace .... ebay ? oubliez ! la perfection vous couterait un bras et 95% de ce que vous y verrez ne vaudra pas le prix payé allez plutôt passer un week end prolongé à Londres ou Glasgow ce sera plus fun et vous trouverez probablement l'un des modèles de la gamme neuf ou presque .... en prime avec le sourire de la vendeuse ... si vous avez de la chance vous trouverez aussi des kits de remplacement..... (lames cuirs pierres pate stropper pour VOTRE MODELE ....les pots de pate ? = impossible à fabriquer (j'ai essayé et pourtant je suis assez bon sur ce point ... la pate Rolls , ça ne s'imite pas !)

Je l'ai déjà dit : quand je poste un objet dans la rubrique revue ne vous précipitez pas sur le marché pour trouver la même chose , pour deux raisons , souvent je présente un modèle "showcase" et trouver celui là m'a parfois pris 10 ans.... alors est ce trouvable à qualité égale ? oui mais généralement pas sur la baie ..... et secondo, je poste les mêmes revues sur des listes de diffusion en anglais allemand et italien et si tout le monde cherche la même chose en même temps vous ferez grimper les prix ....pas la qualité de ce que vous achèterez....

Ceux qui voudraient un rolls de moyen à haut de gamme neuf ou très approchant, (je pense que tout le monde connait mes exigences qualité , mettez vous en file d'attente .... depuis ce soir celle çi a déja trois numéros ...... la patience est une vertu en matière de collection (et même si ce n'est que pour vous raser ....)

Attention les pièces d'un modèle donné ont spécifiques et ne vont généralement pas sur les autres .....!!!

gigabillouPilier

gigabillouPilier

- Messages : 11083

Date d'inscription : 17/07/2013

Age : 60

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Dim 06 Juil 2014, 20:19

Harfff, comment t'es dur Loïc sur les détails

La lame était bien neuve, recouverte de graisse dans son emballage d'origine, les taches sur la pierre doivent venir de cette graisse qui a certainement couler lors de grosses chaleurs, par exemple

Penses que tout le monde n'achète pas pour "stocker" dans un coffre fort mais pour l'utiliser de temps en temps, je respect ton point de vu de la collection, objet totalement neuf, dans son emballage d'origine et aucune traces de doigts sur les objets sous peine de voir diminuer le prix de moitié

Mais comme tu le dis, vous n'êtes qu'une poignet de personnes a procéder une telle collection au niveau mondial, et je veux/peux pas rejoindre une telle confrérie

Voila, j'ai pris du plaisir a utiliser un objet aussi ancien, ca rase aussi bien que certains modèles contemporains et je suis un heureux possesseur de vieux rasoirs

Amitiés sincères Loïc

La lame était bien neuve, recouverte de graisse dans son emballage d'origine, les taches sur la pierre doivent venir de cette graisse qui a certainement couler lors de grosses chaleurs, par exemple

Penses que tout le monde n'achète pas pour "stocker" dans un coffre fort mais pour l'utiliser de temps en temps, je respect ton point de vu de la collection, objet totalement neuf, dans son emballage d'origine et aucune traces de doigts sur les objets sous peine de voir diminuer le prix de moitié

Mais comme tu le dis, vous n'êtes qu'une poignet de personnes a procéder une telle collection au niveau mondial, et je veux/peux pas rejoindre une telle confrérie

Voila, j'ai pris du plaisir a utiliser un objet aussi ancien, ca rase aussi bien que certains modèles contemporains et je suis un heureux possesseur de vieux rasoirs

Amitiés sincères Loïc

pitoufoRéférent

pitoufoRéférent

- Messages : 1580

Date d'inscription : 30/09/2013

Age : 49

Localisation : Madrid-Espagne

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Dim 06 Juil 2014, 22:26

C'est peine perdue, tu le sais Loic n'aime pas le "qui à vécu", je suis sûr que son mobilier a encore le cellophane au cas où il pourrait faire une plus-value

C'est moi qui mon Thierry, on est pas les seuls à aimer la restauration, la rouille à gratter et le plaisir à se raser avec du stuff qui a une âme.

mon Thierry, on est pas les seuls à aimer la restauration, la rouille à gratter et le plaisir à se raser avec du stuff qui a une âme.

C'est moi qui

mon Thierry, on est pas les seuls à aimer la restauration, la rouille à gratter et le plaisir à se raser avec du stuff qui a une âme.

mon Thierry, on est pas les seuls à aimer la restauration, la rouille à gratter et le plaisir à se raser avec du stuff qui a une âme. noarMembre très actif

noarMembre très actif

- Messages : 508

Date d'inscription : 29/11/2014

Localisation : 75013

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Lun 23 Fév 2015, 19:23

c'est vraiment un très bel objet plein d'ingéniosité, je viens de récupérer un modèle viscount quasi NOS, il y a le prix, les docs comme sur le topic de loic, et même la facture (l'acheteur a eu une remise 9,99 usd au lieu de 17,5), seule la pierre est félée.

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Lun 23 Fév 2015, 19:27

Sympa la boite, tu aurais une photo de la facture d'origine ? Ca a l'air intéressant !

noarMembre très actif

noarMembre très actif

- Messages : 508

Date d'inscription : 29/11/2014

Localisation : 75013

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Lun 23 Fév 2015, 19:35

Cha-wing!! a écrit:Sympa la boite, tu aurais une photo de la facture d'origine ? Ca a l'air intéressant !

la facture a rien d'emballant, provient d'un magasin à Detroit, la doc est celle montrée là, photo 4 (j'ai les 2 docs mais pas la feuille de pièce de rechange)

https://onedrive.live.com/?cid=91448dd38c30c162&id=91448DD38C30C162!833&ithint=folder,.JPG&authkey=!AHviMKxMICPo8Wo

copyright loic de nice

mais je n'ai pas la mention traveller set à l'interieur du couvercle et ma boite est toute rouge, elle n'a pas l'effet "lezard?"

PlexusBoss

PlexusBoss

- Messages : 3682

Date d'inscription : 06/01/2016

Age : 56

Localisation : Ch'ti Land

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Mer 25 Oct 2017, 04:32

Une pub en vente sur ebay UK, je publie l'image, instructive (cliquez pour agrandir):

PlexusBoss

PlexusBoss

- Messages : 3682

Date d'inscription : 06/01/2016

Age : 56

Localisation : Ch'ti Land

Rolls Razor Imperial n°1

Rolls Razor Imperial n°1

Sam 11 Nov 2017, 14:23

Salut les poilus !

Un peu hors sujet, le Rolls Razor Imperial n°1 :

C'est le modèle plaqué argent avec manche télescopique.

Il a existé en plaqué or aussi.

Comme je l'ai reçu (la photo du vendeur sur la baie) :

Le déballage m'a sacrement noirci les mains.

Un premier nettoyage et huilage (huile de machine à coudre).

Le mécanisme fonctionnait bien à vide,

par contre, quasiment impossible de tirer la lame sur le cuir, ou de la pousser sur la pierre.

Il a fallu huiler le tube autour de l'axe, sur lequel la lame est fixée, pour résoudre le problème.

Déjà à peu près 4 heures de taf.

20 aller/retour sur la pierre avec quelques gouttes d'eau.

40 aller/retour sur le cuir et rasage :

Mon premier rasage au Rolls :

Juste excellent !

Au plus proche du meilleur jamais obtenu.

Quelques traces de rugosité sous le doigt, à de rares endroits récalcitrants, mais ...

BBS vraiment profond; pas de trace de barbe visible, malgré ma barbe très brune.

Et tout ça sans douleur et très peu de PDS !

Ce rasoir est une arme fantastique !

Un petit échauffement post rasage, vite calmé au Pitralon (merci la Boiboite !).

C'est définitivement mon rasoir préféré de jeudi dernier !

Les affaires se sont corsées dès le lendemain

J'avais bien remarqué qu'il faisait un petit bruit bizarre, un petit cric cric, quand j'appuyais sur le cuir.

La cause :

La grosse épaisseur de colle ou de je sais pas quoi,

qui donne de l'épaisseur au cuir, se désagrégeait totalement,

et faisait tomber des débris, gros comme des grains de sable, dans le mécanisme.

A mon arrivée au Fabricarium, pour remplacer le cuir, le mécanisme était totalement bloqué.

J'ai découpé au laser un bout de cuir de 3 mm d'épaisseur, pour remplacer le cuir d'origine.

Pour l'autre option: remettre le cuir d'origine, débarrassé du brin qui salope tout,

il a suffit de frotter le verso du cuir au dessus d'une poubelle pour que tout se barre.

J'ai découpé un bout de liège de 2 mm d'épaisseur, pour faire un tapis et récupérer l'épaisseur d'origine.

J'ai aussi bossé sur mon support de rasoirs, brosses, coupe choux et brosses à dents, mais là c'est vraiment hors-sujet (sauf qu'il va aussi pour le Rolls Razor) :

Il a fallu tout re-nettoyer encore plus minutieusement.

Virer toute la graisse encrassée de débris de cuir.

Ça m'a coûté deux brosses à dents !

Et ce coup ci j'ai re-graissé le mécanisme à l'huile de silicone.

Le trempage de la lame avec le reste l'a carrément noircie, erreur !

Ponçage au grain très fin ( 3000 - 5000 - 10000 ), pas aussi polie qu'avant, mais bonne récupération :

A noter que les couvercles ne semblent pas plaqués argents, contrairement au reste.

Soit ils ne sont pas d'origine, soit si quand même, vu que les pièces de remplacement,

cuir et pierre, étaient peut-être vendues avec leur couvercle.

Le manche est différent de celui de l'Imperial n°2,

il est télescopique, avec une bille de serrage, montée sur ressort, pour un emboîtement "en force".

Pratique et ingénieux pour à peu près tout,

sauf pour fixer la lame, ou ça s'avère plus compliqué.

Aller je vous laisse, pour fêter l'armistice,

et me raser avec un rasoir conçu pendant la première guerre mondiale.

Thirteen British patents were issued between 1917 and 1950 and eight U.S. patents were issued in 1918-1951.

Un peu hors sujet, le Rolls Razor Imperial n°1 :

C'est le modèle plaqué argent avec manche télescopique.

Il a existé en plaqué or aussi.

Comme je l'ai reçu (la photo du vendeur sur la baie) :

Le déballage m'a sacrement noirci les mains.

Un premier nettoyage et huilage (huile de machine à coudre).

Le mécanisme fonctionnait bien à vide,

par contre, quasiment impossible de tirer la lame sur le cuir, ou de la pousser sur la pierre.

Il a fallu huiler le tube autour de l'axe, sur lequel la lame est fixée, pour résoudre le problème.

Déjà à peu près 4 heures de taf.

20 aller/retour sur la pierre avec quelques gouttes d'eau.

40 aller/retour sur le cuir et rasage :

Mon premier rasage au Rolls :

Juste excellent !

Au plus proche du meilleur jamais obtenu.

Quelques traces de rugosité sous le doigt, à de rares endroits récalcitrants, mais ...

BBS vraiment profond; pas de trace de barbe visible, malgré ma barbe très brune.

Et tout ça sans douleur et très peu de PDS !

Ce rasoir est une arme fantastique !

Un petit échauffement post rasage, vite calmé au Pitralon (merci la Boiboite !).

C'est définitivement mon rasoir préféré de jeudi dernier !

Les affaires se sont corsées dès le lendemain

J'avais bien remarqué qu'il faisait un petit bruit bizarre, un petit cric cric, quand j'appuyais sur le cuir.

La cause :

La grosse épaisseur de colle ou de je sais pas quoi,

qui donne de l'épaisseur au cuir, se désagrégeait totalement,

et faisait tomber des débris, gros comme des grains de sable, dans le mécanisme.

A mon arrivée au Fabricarium, pour remplacer le cuir, le mécanisme était totalement bloqué.

J'ai découpé au laser un bout de cuir de 3 mm d'épaisseur, pour remplacer le cuir d'origine.

Pour l'autre option: remettre le cuir d'origine, débarrassé du brin qui salope tout,

il a suffit de frotter le verso du cuir au dessus d'une poubelle pour que tout se barre.

J'ai découpé un bout de liège de 2 mm d'épaisseur, pour faire un tapis et récupérer l'épaisseur d'origine.

J'ai aussi bossé sur mon support de rasoirs, brosses, coupe choux et brosses à dents, mais là c'est vraiment hors-sujet (sauf qu'il va aussi pour le Rolls Razor) :

Il a fallu tout re-nettoyer encore plus minutieusement.

Virer toute la graisse encrassée de débris de cuir.

Ça m'a coûté deux brosses à dents !

Et ce coup ci j'ai re-graissé le mécanisme à l'huile de silicone.

Le trempage de la lame avec le reste l'a carrément noircie, erreur !

Ponçage au grain très fin ( 3000 - 5000 - 10000 ), pas aussi polie qu'avant, mais bonne récupération :

A noter que les couvercles ne semblent pas plaqués argents, contrairement au reste.

Soit ils ne sont pas d'origine, soit si quand même, vu que les pièces de remplacement,

cuir et pierre, étaient peut-être vendues avec leur couvercle.

Le manche est différent de celui de l'Imperial n°2,

il est télescopique, avec une bille de serrage, montée sur ressort, pour un emboîtement "en force".

Pratique et ingénieux pour à peu près tout,

sauf pour fixer la lame, ou ça s'avère plus compliqué.

Aller je vous laisse, pour fêter l'armistice,

et me raser avec un rasoir conçu pendant la première guerre mondiale.

Thirteen British patents were issued between 1917 and 1950 and eight U.S. patents were issued in 1918-1951.

PlexusBoss

PlexusBoss

- Messages : 3682

Date d'inscription : 06/01/2016

Age : 56

Localisation : Ch'ti Land

Re: Rolls Razor Imperial N°2

Re: Rolls Razor Imperial N°2

Sam 11 Nov 2017, 16:11

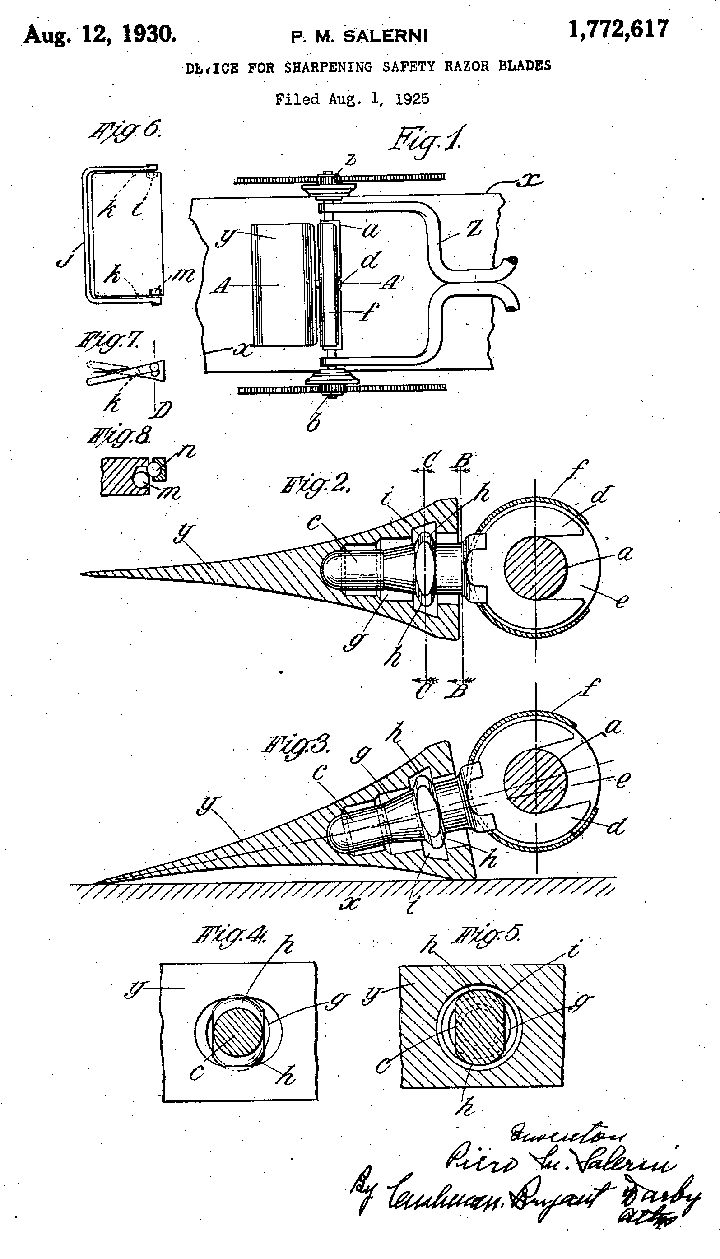

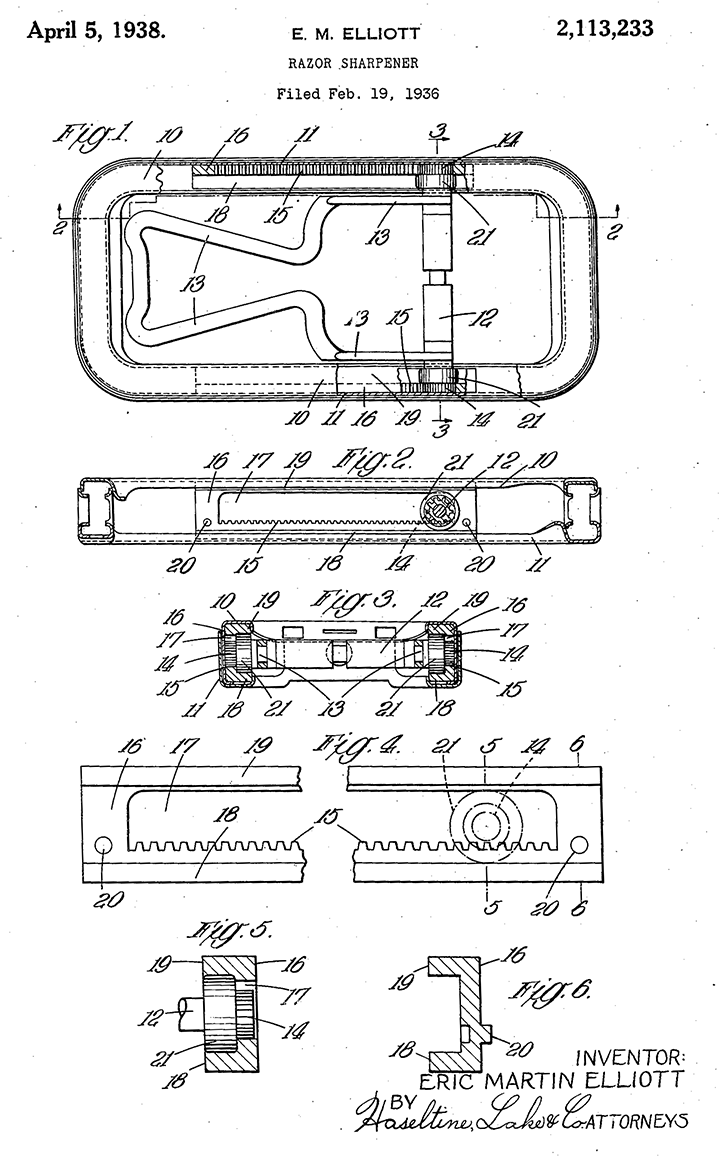

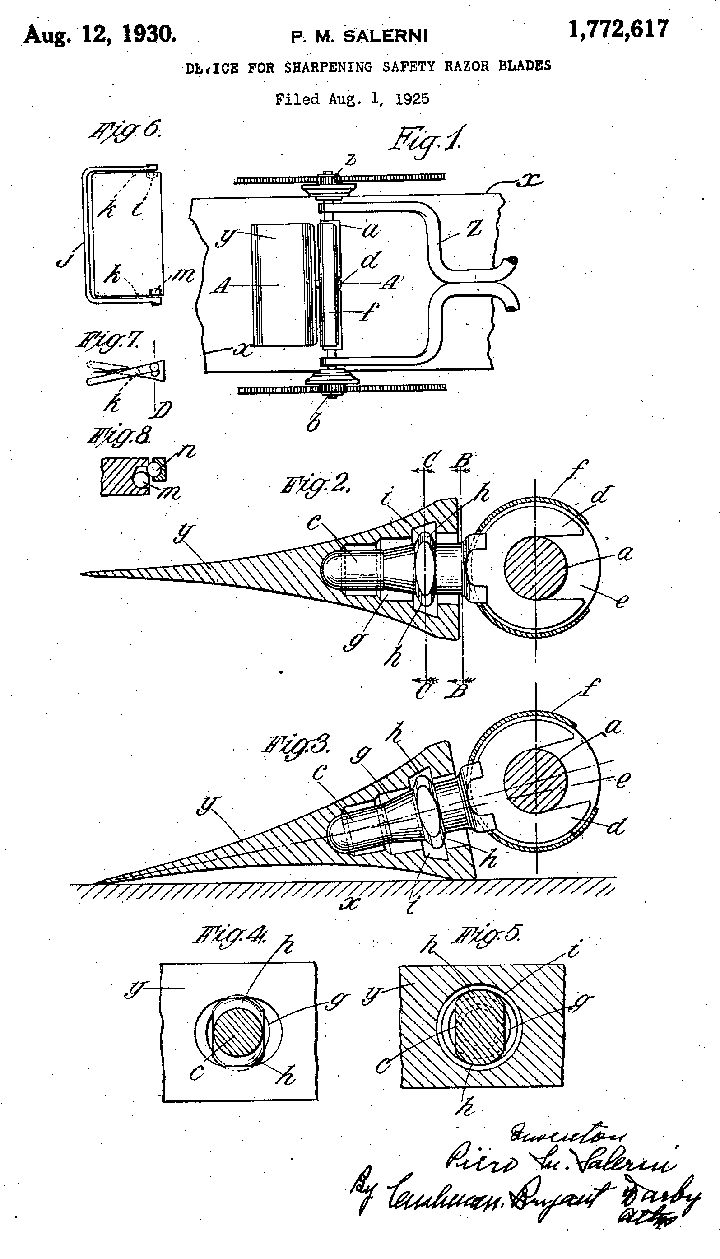

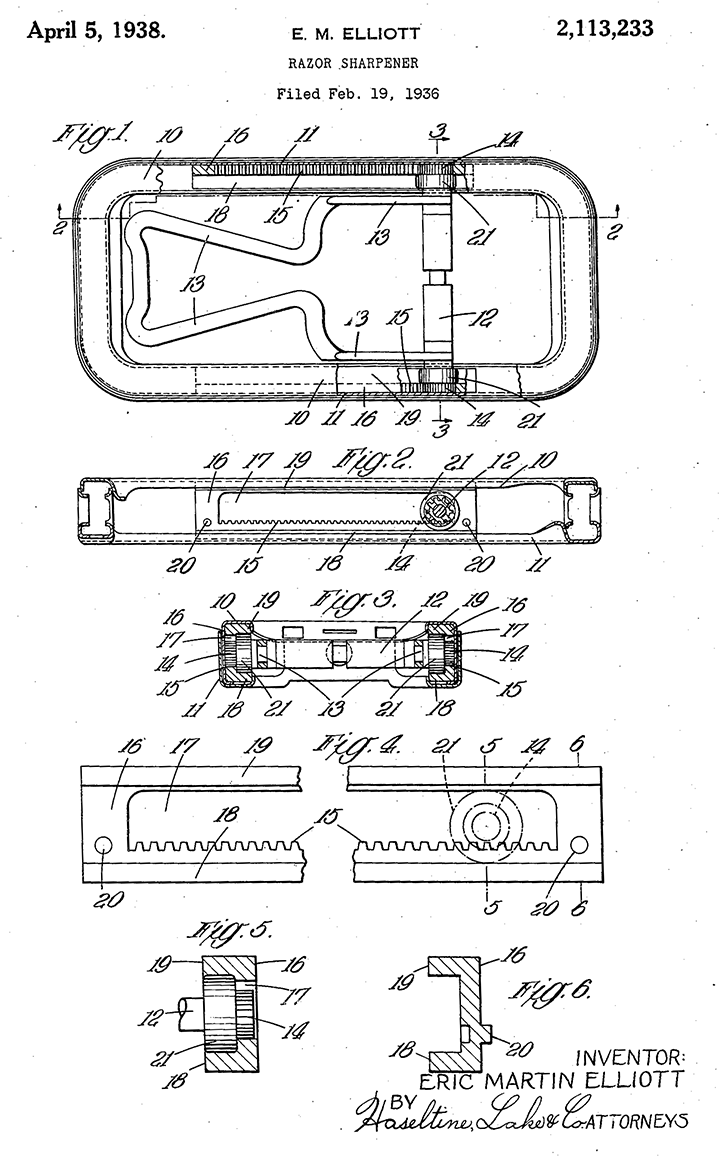

Autres images intéressantes celles des brevets :

Principe de l'auto-affûtage des lames: US1772617 A

Brevet déposé en 1930 aux US mais datant de 1924 en UK :

Boitier des modèles Imperial et Viscount : US2113233

Brevet déposé en 1938 aux US mais datant de 1936 en UK :

Manche du modèle Imperial n°1 et Viscount : US2517794 A

Brevet déposé en 1950 aux US mais datant de 1944 en UK :

On peut donc en déduire que nos modèles datent tous des années 40 à 50.

Principe de l'auto-affûtage des lames: US1772617 A

Brevet déposé en 1930 aux US mais datant de 1924 en UK :

- DESCRIPTION (OCR text may contain errors):

- Aug'lz, 1.930. P.. M. SALRN. 1,772,617

DIMICE FOR SHRPENING SAFETY vRAZOR BLADES Filed Aug. 1, 1925 Patented Aug. 12,1930

A.as

lwafer type of blade.

UNITED STATES lPATENT oFFlcE HERO MARIANO sALEnNI, oEsYDENHAm HILL, Lon-Don; ENGLANIS, Ass'IeNon, BY

COMPANY 0F GREAT BRITAIN i MESNE ASSIGNMENTS, T0 ROLLS RAZOR (1927) LIMITED, QF-LONDON, ENGLAND, A

DEVICE FOR SHARPENING SAFETY-RAZOR BLADES Application led August 1, 1925, Serial No. 47,627; and in Great Britain August 16, 1924.

The present invention relates to devices for sharpening safety razor blades, of the kind in which the blade is automatically rocked at the end of each stroke to reverse it and is automatically caused to bear on the whetting or sharpening surface during the strokes, there being provision for automatic adjustment of the edge lof the blade on the said surface considering said surface transversely to the direction of the strokes, the blades dealt with being of the comparatively rigid type and approximately wedge-shaped in cross section in distinction to a iexible or By the term wedgeshaped it is to be understood that I include all blades which are thicker at the back'so that when they lie on a surface an imaginary straight line passing through the middle 4of the thickness of the back to the edge would be at an angle to that surface and whether the blade be made entirely in one piece or the additional thickness at its back part be made by securing a part or parts thereto. In both honing and stropping such approximately wedge-shaped blades, and particularly in honing, it is necessary or very desirable that the angle at which the edge of the` blade is presented to the whetting or sharpening surface be always the same and it is also advantageous that this angle shall be as small as possible. The main object ofthe present invention is to attain these advantages in safety razor sharpening devices of thekind referred to. Y

In safety razor sharpening devices of the kind referred to the razor blade is connected to a carrier which is reciprocated over thel whetting or sharpening surface and according to the said invention the connection devices are adapted to allow the blade to adjust itself -on .the whetting or sharpening surface angularly in a direction from edge to back or vvice versa, whereby as the blade is presented to the whetting or sharpening surface it adjusts itself so that both its back part and edge bear thereon in a oating manner duringthe stroke.v Consequently any variation in distance between the axis of the carrier' and the whetting or sharpening surface either at different parts of the .same apparatus or in tyrazor blades of the kind referred to as l heretofore known the blade has been removably connected'to the carrier by meansof a pin on the carrier engaging in a hole in the `back of the blade in which hole the pin has a working fit. With this kind of connection the lpresent invention may be conveniently embodied by providing that while the pin has a working bearing at ornear the bottom ofthe hole its diameter is smaller than the diameter of the hole or its width in the direction of the thickness of the blade from the bearing pzltrt of the pin Jutwardly, to aiford room for p ay. may be conveniently provided by the hole having an increased diameter from the bearing part for the Din outwardly. The bearing part for the pinV in the blade is preferably about midway between the back and edge of the blade or as near the middle as feasible having regard to the thickness of the blade at that art. Thus the blade may tilt or rock angu arly on theinner end portion of thel in. Toprovide that the blade shall be locke on the pin during useof the sharpening device an abutment or abutments ma be provided on the pin at a suitable part t ereof located orto be located within the hole in the blade,

say at a short distance from the outer end of 75.v This relative difference in diameter pin the size of the recess or recesses being l rocking movement of the blade on the en p thefpin isnot interfered with by the abutments referred to yet they prevent the blade such that while the freedom of the tilt-ing o;

leaving the pin in the reversal and whetting movements. In order to provide for the blade being engaged with pin and disengaged therefrom the abutment or abutments on the pin may project or be situated only in one direction transverse to the axis of the pin o r project substantially less in that direction as compared with a direction at right angles thereto and the outer part of the hole in the blade between the recess or recesses therein and the back of the blade may be of a slot-like or elliptical shape, its larger diameter being at right angles to and a little larger than the greatest diameter across the abutment or abutments on the pin whenthe blade is on the pin in the sharpening position and the smaller diameter of the outer part of the hole is such that the abutment or abutments on the pin at the least dimension across it or them or the portion between it or them can pass through it. The result 'of thisprovision isthat the blade may be connected with the pin by placing the hole in the' blade over the pin on the carrier while the blade is at right angles to the axis of the carrier and then turning the blade through an angle of about 90 and the blade may be disconnected by reverse action.

In order that the said invention may be better understood and carried into practice the preferred embodiment thereof is hereinafter particularly described with reference to the accompanying drawings which illustrate by way of example an embodiment of the invention in a known form of a razor sharpening device of the kind hereinbefore referred to. Y

Figure 1 of the said drawings is a fragmentary somewhatv diagrammatic plan view of the carrier for the blade in the razor sharpening device with the blade connected thereto. Figure 2is a section taken on the line A, A Figure 1, showing som'e parts in side view, Figure 3 is a sectional view similar to Figure 2 but showing the blade and the adjacentA parts of the carrier in the position they adopt when the blade is being traversed over the sharpening surface, Figure 4 is a sectional view taken on the line B, B Figure 2, and Figure 5 is a sectional View taken on the line C, C' Figure 2. The said sections Figures 4 and 5 only show the parts adjacent to the connection between the carrier and the blade. Figures 6, 7 and 8 are respectively a face view, end view and detail in section `on the line D in Figure 7 illustrating the guard member hereinafter described preventing also the edge of the blade striking the sharpening surface before the back part.

Figures 2-5 are drawn to a larger scale than Figures 1, 6, 7 and 8. y

In the following description the 'parts of the said drawings are referred to by the letters marked thereon and the same letters indicate the same parts in all the figures.

in connection with which the invention is illustrated is that in which the blade is temporarily connected with a carrier consisting of a spindle carrying a toothed wheel at each side meshing vwith racks whereby the spindle is rotated as the carrier is reciprocated and the blade is.k connected with the carrier through the medium of a pin engaged in a hole in the blade, the said pin having a fork or yoke which engages the spindle of the carrier at a reduced part thereof so that the said spindle may rotate independently of the pin, a friction device being provided around the spindle, in the form of a sleeve of resilient material such as steel embracing the spindle with resilient pressure, the said pin being engaged in a hole in the said sleeve so that the sleeve and pin may turn together. In the said drawings m is the whetting or sharpening surface, a is the spindle of the carrier, b, l) the said toothed wheels, c the pin provided at d with a fork or yoke engaging in 'thereduced part of the spindle at e and f is the sleeve of resilient material. y is the Iblade and z is a part of the handle by which thecarrier is reciprocated. The parts referred to may be taken to be parts of a device for honing and stropping such as described in United States Patent 1,512,058 v and ,in the accompanying drawings the parts are shown as arranged for honing. As lthe carrier of the device is reciprocated the spindle rotates and due to the friction of the sleeve f on the spindle a the blade is caused to bear against the whetting or sharpening surface and at the end of a stroke the said friction is suiiieient to reverse the blade and cause it to strike the whetting or sharpening surface at the beginning of its next stroke in the direction opposite to that of its previous stroke. These features are no part of the present invention which relates as should be understood from the description hereinbefore given, to the connection between the carrier and blade'to allow the blade to adjust itself and bear on the whetting or sharpening surface in the floating manner hereinbefore referred to. To this end in the embodiment illustrated the end of the pin c is hemispherical and has a workino bearing in the bottom of the hole g in the blade but at the other parts the said hole has as shown a diameter substantially larger than that of the pin to afford room for play between the pin and the blade and to enable the end of the pin c to cause the blade to bear on the whettin or sharpening surface both at its back an edge parts notwithstanding any variation there may be from time to time or in different apparatus in the distance between l the axis of the spindle a and the whetting or sharpening surface, the blade thus tilting or rocking angularly as may be necessary on the inner end portion of the pin as the blade is brought on to the whetting or sharpening surface and while the bladel is being caused to bear on that surface during a stroke if there be any variation in that surface. The blade may also turn slightly on the pin to adjust itself on the .whetting or sharpening surface considering said surface transversely to the direction of reciprocation of the carrier although this feature so far as. the edge 'of the blade is concerned, is ,not novel in itself. It ispreferred that the inner end of the pin shall be hemispherical and the bottom of the hole of corresponding shape so that the blade may tiltor rock in the required direction or directions on the end of the pin after the manner of a ball joint, but

- the end of the pin may be of other forms as for instance conical, the point having a bearing at the apex of aconical shape of shal- ,20' lower angle given to the bottom of the hole.

In order to provide that the blade shall be locked on the pin c during use of the sharpen-- ing device abutments 7L, L are provided on the pin at such a part that they are located and free to play to a limited extent in the circular recess i a little distance from the back of the blade and of a larger diameter than the outer end of the hole g in the blade that is that pa'rt of it which constitutes the passage between the said recess i and the back ofthe blade through which the pin` is passed and in which it isl partly located. The abutments it, it are formed by forming flats at opposite parts of an annular shoulder originally so formed on the pin c. The

abutments L, 77, do not interfere with the freedom of the blade to tilt or rock to a limited extent on the end of the pin as described lbut nevertheless prevent,- the blade leaving the pin during the whetting operation. When the blade is being honed it is caused to pass over and bear on the whetting or sharpening surface with its edge foremost by the end of the pin c working and bearing on the bottom of the hole in the blade without interfering with any tilting or rocking of the blade and'therefore there is no tendency for the blade to leave the pin during the stroke but nevertheless an abutment such as those at L is necessary at least to prevent the blade leaving the pin during the reversal movement of the blade. blade it is caused to pass over the stropping surface with its back foremost and in this case although the end of the pin c' puts pressure on the blade, the blade is drawn overthe stropping surface through the mediuml of the abutments h, h bearing against the outer wall of the recess i and they also prevent the bladeleaving the pin during reversalmovementof the blade.

` vide for the blade bein engaged with 4the pin c and disengaged t erefrom the abutments h, are opposite one another leaving a portion between them of less width In stropping al In order to pro in a direction'l across the sharpening surface and the outer end of the hole inthe blade or the passage between the recess z' and the back of the bladeis of greater diameter in a direction across the sharpening surface than in a direction at right angles thereto the smaller diameter of that part of the hole or the passage being slightly greater than thewidth or diameter of the portion between the abutments h, and greater than the diameter of the .outer part of the pin c but smaller than the dimension across the abutments h, 11, so that although there is freedom of play at that part between the blade and the pin yet the abutments L, L prevent the blade being removed from the pin when the parts are inthe positions illustrated. The greater diameter or width of the passage referred to is as shown in Figure 4, a little larger-than the dimension across the abutments h, h. It will therefore be realized that .the connection between the pin and a blade is of a bayonet joint-like character that is the hole in the blade is'engaged with the pin cA by being ,passed thereoverl while the blade is in a position at rightanglestothe axis ofthe' spindle a and then when .the abutments 7L, L are within the recess i the blade is turned through about 90 into the position illustrated in the drawings. This bayonet jointlike connection between the blade and the carrier does not however in itself form any part of the presentdnvention. It is convenient that the bearing of th inner end of the pin o in the hole in the blade should be a considerable distance from the back part as illustrated and this distance may suitably be between one third and one half the distance from the back of the blade to the edge or as near the middle fromback to edge as feasible having regard to the thicklness of the blade so that the pressure of the end of the pin is applied to such part of the blade that theedge of the blade is caused to bear on the whetting surface with av desirable degree of pressure as well as the back of the blade. v

It will be seen by examining Figure 3 which shows the blade and parts in the position they take up and retain during the stroke that there is substantial facility for adjustably tilting or rocking movement of the blade on the end of the pin c so that the blade bears on the whetting or sharpening surfaceboth at its back part and edge part at all times during the stroke notwithstanding any irregularities in the surfaceor .variation of the distance o f the aXis of the spindle a from the whetting or sharpening surface; consequently the angle at which the edge ofthe bla de is presented to the whetting or sharpening surioo face is always the same and that angle is as small as possible. f

bladetis being presented ito the whetting or causing the blade to tilt so that the back partv bears on the whetting or sharpening surface before the pressure is sufficient to bring the edge into contact with the surface against resistance of the member to movement -relatively to the blade. Such a member may be functionally constituted by a guard member to prevent injury to the fingers and/or a guard to act as such in shaving such as illustrated in Figures 6, 7 and 8 in which j is the guard member pivoted to the blade at k, c, so that it may be moved from one side of the edge of the blade to the other. The arms of the guard member are slightl resiliently displaceablefrom the ends of t e blade and one arm` carries a pin working in a recess Z of greater diameter than the pin to limit the movement of the guard member and at the other arm of the gJuard member is the device to retain the mem er temporarily in position to one or other side of the blade, the device also causing the latter art of the movement of the guard member 1n either direction to' take place automatically. This device consists of a sphere m arranged in a recess in the blade and having some freedom of lateral movement therein in a direction across the thickness of the blade and a projection n on the. end of the arm of the guard member which projection rides over the 'outer ortion of the s here against the resilience of t e arm when t e guard member is moved towards and past the edge of the blade. The project1on n 1s form of a steel sphere secured in a recess 1n the arm by pressing the adjacent metal around the sphere.

The invention is not limited to the form or arrangement and 'details described and illustrated as these may be' varied very substantial'ly without departing from the spirit of my invention. l Y

What I claim and desire to secure by Letters Patent of the United States is Y i 1. In combination in a safety razor blade sharpening device, sharpening material, a reclprocable carrier. for theblade, means to automatically rock the\blade at the end, of

each stroke to reverse it, means to cause the` blade automatically to `bear on the sharpening surface ofsaid material during the stroke and connection .devices between the carriery and the razor blade permitting of adjustment of the blade edge on the sharpening surface considering said surface transversely to the direction of reciprocation of the carrier andV distance from the back of the blade towardsv the edge part to enable the blade to adjust itself on the sharpening surface so that bothl its back part'and edge part bear thereon through the stroke without restraintby the said connection devices. l

2. In combination in a safety razor blade sharpening device, sharpening material, a reciprocable carrier for the blade, means to automatically rock the blade at the end of each stroke to reverse it, means to cause the blade automatically to bear on the sharpening surface of said material during the stroke, and a pin on the carrier engaging in a hole in the back of the blade, the said pin having a working bearing at or near the bottom of the hole and having a diameter smaller than the width of the Ahole in the direction of the thickness of the blade, from the bearing part of the pin outwardly, to ai'ord room for sullicient angular play between the pin and the blade to enable the back part of the blade as well as its edge part to adjust themselves on the sharpening surface without restraint by the said pin.

3. In combination in a safety raior blade sharpening device, sharpening material, a reciprocable carrier for the blade, means to automatically rock the blade at the end of each stroke to reverse it, means to cause the blade automatically to bear on the sharpening surface of said material during the stroke, a pin .on the carrier engaging in a hole in the back part of the blade, the said pin having a Working bearing at or near Athe bottom of the hole and havinga diameter smaller than the width of the hole in the direction of the thickness of the blade,'from the bearing part of the pin outwardly, to afford room for suiiicient angular `play between the pin and the blade to enable the back part of the bladeas well as its edge lpart to adjust themselves on the sharpening surface without restraint by the said pin,vand an abutment or abutments on the said pin to en age in a recess or recesses Ain the hole inthe lade to prevent the blade leaving the pin during operation of the sharpening device.

4. In combination in a safety razor blade sharpening device, sharpening material, a reciprocable carrier for the blade, means to automatically rock the blade at the end of each stroke to reverse it, means to cause the blade automatically to bear on the sharpening surface of said material during the stroke, a pin on the carrier engaging in a hole in the ack part of the blade, the said pin having a working bearing at or near the bottom of the hole and havin a diameter smaller than the wrdth of the ole in the direction of the thickness of the blade, from the bearing part ments on ofthe pin outwardly,

recesses in the hole in the blade to prevent the that the samemay blade leaving the pin during operation of the sharpening device, the said abutment' or abutments constituting a substantially radial projection or projeetlons and the opening part of the hole having a larger diameter in one plane than the diameter in a plane at right angles thereto in order to afford for a bayonet joint-like connection between the blade and carrier.v

5. In combination in a safety razor blade sharpening device, sharpening material, a carrier for the blade, saidcarrier being reciprocable in a definite path above said material, means to automatically rock the yblade at the end of each stroke toreverse it, means to cause the blade to automatically bear on "the sharpening surface of said material during the i stroke, and connection devices between the carrier and the razor blade adapted to allow the blade to adjust itself on the sharpening surface so that both the vback part and edge part of the blade -bear on the said surface through the stroke Without restaint by the' said connection devices notwithstanding the definite path of reciprocation of the carrier;

PIERO MARIANO SALERNI.

CERTIFICATE 0F CGRRECTION.

mehr No. 1,172,611.

mno MARIANO smul.

name of the assignee in the Vabove numbered patent was erroneously written 'and printed as "Rolls Razor (1927) Limited, Aof imam. angina, a muy of crm Britain", whereas said me should have been written and printed as Rollsrlhnor Limited, of London, England, a company of Great Britaimas shown by the records of assignments in this office; and that the said Letters Patent should be read with this correction therein conform tothe record of the case in the Patent Office. Signedand sealed this 21st day of October, A. D. 1930.

tu isherqbyferrified am me M. J. Moore,

(Seal) Y Y Acting Conlnissioner of Patents.

GrantedAnguet 12, 1930, to`

Boitier des modèles Imperial et Viscount : US2113233

Brevet déposé en 1938 aux US mais datant de 1936 en UK :

- DESCRIPTION (Le texte OCR peut contenir des erreurs.):

April 1938. E. M. ELLIOTT 2,113,233

RAZOR SHARPENER Filed Fb. 19, 1936 4. 17 11 A "13L I v 1% 1J 111a 211; 21 16 16' 1 7 19 W4 31 J 4 4 4 F/ 3 v [a Q Z/ f5 INVENTOR= ERIC MARTIN ELLIOTT 5v mo e flmwavs Patented Apr. 5, 1938 UNITED STATES nszoa SHARPENER.

Eric Martin Elliott, Watford, England, assignor to Rolls Razor Limited, London, England, a

British company Application February 19, 1936, Serial No. 64,719 In Great Britain February 26, 1935 2 Claims.

The present invention relates to devices for sharpening safety razor blades of the kind in which the blade is automatically rocked or reversed at the end of each stroke and provision is made for honing or stropping the blade (or both), see for example the specifications of Patents Nos. 1,266,183 and 1,512,058. The chief object of the present invention is to provide a means of construction of the razor box or casing whereby the said razor box or casing is suitably reinforced to enable better and more accurate engagement of the gearing racks and the spindle pirnons to be obtained.

According to this invention the form of the -razor box or casing is thickened or stiffened in cross section, or suitable parts are secured to such box or casing to provide a thickening or stiffening along those portions (herein called tracks) traversed by the spindle or its guiding wheels, rollers or the like in order rigidly to receive and resist the resultant gearing stresses from the spindle pinions meshing with their respective racks and other applied forces. The spindle in such forms of razor sharpening devices referred to is disposed centrally by the guiding wheels or rollers between the inner faces of the tracks, and the gearing racks are suitably disposed to allow the spindle pinions to mesh therewith.

The said thickening or stiffening of the razor box may be provided by riveting or otherwise securing a member or members of suitable crosssection to and within each longitudinal side of the razor box or casing, such member or members being so disposed as to provide suitable tracks for each spindle guiding wheel or roller. Such thickening or stiffening members may be of channel form in cross-section and secured within the longitudinal sides of the razor box or casing so that the base of each channel section is adjacent and parallel to each such longitudinal side of the razor box or casing, the inner faces of the open arms or legs of the channels providing uninterrupted tracks for the spindle rollers. Such channel sectioned members may have suitable portions cut away to allow of the gearing racks being also mounted and secured within the longitudinal sides of the razor box or casing and also to allow of the meshing of the spindle pinions with the said gearing racks.

The stiffening members may have the gearing racks secured to them, or advantageously formed directly on the material of said thickening or stifiening members. In one embodiment, the thickening or stiffening member is formed of channel sectioned material having a slot centrally disposed along part of the base of the channel preferably nearer to one channel leg'to allow suitable rack teeth to-be out or formed in one longitudinal side of the slot. The pitch line of such rack teeth is so disposed from the inner faces of the channel arms as to admit of the meshing of the spindle pinion with said rack teeth.

Each spindle guiding wheel or roller may be of one piece or of composite form, and of cylindrical shape. In one embodiment of the invention the spindle guiding wheel or roller may have one or more flats on its periphery so that instead of rolling within the track it slides therein, while the sliding member has its spindle bearing hole formed so that in situ the spindle is nearer to one of the inner track faces than to the other. The spindle may also be so increased in size as to bear directly on the tracks, so that the spindle guiding wheel or roller is dispensed with.

In order that the invention may be clearly understood and readily carried out, the same will now be more fully described with reference to the accompanying drawing, in which:-

Figure 1 is a plan View partly in section of one embodiment of the present invention, showing in particular the operating handle and the blade carrying spindle, which latter has mounted thereon the pinions that engage with the racks at the sides of the razor box or casing.

Figure 2 is a longitudinal sectional view taken on the line 2-2 of Figure 1.

Figure 3 is a cross-sectional view taken on the line 3-3 of Figure l.

Figure 4 is an enlarged side View of one of the racks in accordance with this invention.

Figures 5 and 6 are cross-sectional views taken on the lines 55 and 6-6 respectively of Figure 5.

As shown in Figures 1 to 3, the casing or box is constituted by two parts or frame members it! and l I, the former fitting in the latter and being secured in position in any suitable or usual manner. The two frame members In, H are closed by oppositely disposed removable honing and stropping surfaces (not shown) along either of which the razor blade when mounted on the spindle l2 can be rocked as a result of moving the handle 13 backwards and forwards to cause the pinions 14 mounted on the ends of the spindle l2 to travel along the racks I5 and effect the necessary angular movement of the spindle and the blade which is removably mounted in a carrier (not shown). In the example shown, each :ithe channel sectioned strips I6.

rack I5 is formed or provided in a channel sectioned strip I6 having a longitudinal slot I! in the base or main part of the strip which lies against the walls of the frame member I8 and also carries the arms or extensions I8 and I9 to provide the channel section. In the example shown, each rack I5 is integral with the strip (although it may be separately attached in some cases) and the rack teeth extend along the length of the slot H which is of such dimensions as to receive one of the pinions I4 on the spindle I2. The said channel sectioned strip I6 may be secured in position in any appropriate manner by turning over the edges of the interfltting frame members I and II as shown in Figure 3, and in one example locating projections or pins 20 (see Figure 6) formed on the channel sectioned strips I6 may project into holes in the sides of the frame member ID. The two rack members are identical in construction and they may be extruded or stamped so that the teeth of the racks I and the aforesaid pins or projections are all integral with. the mainpart of the channel sectioned strip. As previously stated, the slots FL" in the channel sectioned strips are of such dimensions as to receive the pinions I4, and adjacent to the said pinions and mounted on the said spindle are rollers 2| which are adapted to bear either on the arms I8 or the arms I9 of These lower arms I8 form tracks along which the rollers 2I travel and revolve as the spindle is moved backwards and forwards by the handle, during which time the pinions engage with the racks in order n to effect the necessary angular movement of the spindle as required, for honing purposes. When the box or casing is reversed or inverted and used for stropping purposes, the rollers 2| bear on the tracks constituted by the arms I9. The

- sectioned strip which provide thetracks along Which the guiding wheels or rollers 2I travel, resist the gearing stresses resulting from the spindle pinions I4 meshing with their respective racks I5, together with other applied forces.

Although it is preferred to provide reinforcing or stiffening members in the form of channel sectionedstrips, it will be understood that other forms of strips may be used. Although the rack is integrally formed with the channel sectioned strip, it will be understood that separate racks may be provided, and in such case they may be inserted in or fixed on the reinforcing strip in any appropriate manner, for example by rivets or otherwise. Although in the example shown the guiding wheels or rollers are of cylindrical formation and roll on the track surfaces, there may be provided members that travel along the said tracks without rolling. For instance, guiding members similar to those represented by the reference 2| may be provided with a fiat or flats at the periphery to engage with the track or tracks, so that instead of a rolling action along the track, a sliding action takes place. In a further modification, the spindle itself may be increased in size'ordiameter so as to roll or slide directly on the tracks, in which case separate guiding wheels or members can be dispensed with.

What I claim and desire to secure by Letters Patent of the United States is:

1. A razor sharpening device of the character described, comprising a casing, a portion having a sharpening surface, sliding means in the easing for carrying a razor blade and causing it to move in contact with said sharpening surface, rotatable pinions on said sliding blade-carrying means and reinforcing means consisting of channel-sectioned strips afiixed to the longitudinal sides of the casing, the main part of the channel-sectioned strips lying adjacent to and parallel with said longitudinal sides, and racks carried upon said main part of said strips and adapted to be engaged by said pinions, while the inner surfaces of the arms of the said strips constitute bearing tracks, andmeans associated with the slidable blade carrying means for bearing on said tracks which resist the resultant stresses arisingfrom the pinions meshing with their respective racks and from other applied forces.

2. A razor sharpening device according to claim 1, in which each channel-sectioned strip has a longitudinal slot in the main part lying parallel with the longitudinal sides of the casing and disposed between the lateral arms forming the bearing tracks one edge of said longitudinal slot having rack teeth adapted to be engaged by the respective pinions both for honing and stropping purposes, said bearing tracks being respectively used in turn, the one track when stropping and the other track when honing.

ERIC MARTIN ELLIO'I'I'.

Manche du modèle Imperial n°1 et Viscount : US2517794 A

Brevet déposé en 1950 aux US mais datant de 1944 en UK :

- DESCRIPTION (OCR text may contain errors):

- Aug. 8, 1950 E. H. LAW

SAFETY RAZOR Filed nec. 23, 1944 Patented Aug. 8, 1950 SAFETY RAZOR Edgar Harold Law, Gerrards Cross, England, assignor to Rolls Razor Limited, London, England, a company of Great Britain Application December 23, 1944, SeralNo. 569,458 In Great Britain January 26, 1944 The invention relates tc safety razors of the kind in which the blade is removablyattached to a handlewhich for the purpose, has a jaw-like gripping head, in which the blade is adapted to be engaged and held in position by a pressure member, the invention being more particularly applicable to the case where a comparatively rigid razor blade is used in a contra-distinction to what is known asa wafer blade.

The object of the invention is to provide an improved form of handle for this `kind of razor.

'I-Iitherto, in constructing the handle, the practice .has been to make the gripping head as one piece and the handle proper as a separate piece, the two being screwed or otherwise joined together, the handle proper being provided with a bore accommodating a spring-pressed ball which projects into the gap in the gripping head so as to press upon the blade when the latter is inserted in the head and which is restrained against total ejection by a displacement of the metal at the end of the handle.

It has been found that in order that the razor blade when applied to the gripping head, shall be retained therein with sufficient security, considerable spring pressure has to be applied to the ball. The ball is, for convenience, of small size and, because of the spring pressure necessarily imposed on it, difficulty is experienced in making the restraining means strong enough to ensure that the ball will not be totally ejected from the handle proper when the blade is not present.

One of the objects of the present invention is to provide a construction overcoming these drawbacks. A further object is to provide a construction which is more robust and serviceable than those of the earlier form, and one which presents no serious manufacturing diiculties.

In accordance with the present invention, the member adapted for applying pressure ,to the blade when inserted in the gripping head, takes the form of a rod or plunger which is accommodated within the .handle proper and is movable for Asolid or resilient .engagement with the blade.

`:Inorder that the invention maybe more readily understood, three embodiments thereof are illustrated `in the accompanying drawings, in which:

Figure l is a longitudinal sectional viewgof `the handle acconding `to the first embodiment, the parte being 4shown in `a :position ready for application of the blade;

Figure 2 `isa longitudinalsection partly in elevation of `:the handlaindicatingthe position as- 55 ing the blade `in rearwardly. If `it is not suIii-1 3 Claims. (Cl. 30-62) sumed by theparts when the blade is applied and secured;

Figure 3 is a view similar to that `of AFigure 2, illustrating Athe second embodiment;

Figure 4 is a view again similar to that of Figure 2, but illustrating the third embodiment.

In the embodiment illustrated in Figures `1 and 2, `the gripping head l and the handle proper 2, or more strictly speaking, the upper part of the handle proper, are made in one piece as by machining from a `metal blank. The handle proper is divided about midway between its ends into two separa-te parts 3 and 4, the part 3 (the upper part) carrying the gripping "head I having a bore 5 which communicates with the wedge-like gap `l inthe head and accommodates, with a sliding lit, a thrust rod 'l `the upper extremity of which is preferably rounded as indicated at 8 and the lower end of which is engaged in a recess 9 in the top of the other part 4 (the lower part) of the handle proper.

In Lthe .base of the handle part 3 there is provided a screwethreaded recess l!) adapted to receive a screw-threaded reduced portion Il at the upper end of the handle part 4. `The open lower end of therecess ill is preferably enlarged as indicated at I2, so that when the two parts of the handle are `fully screwed together, the enlargement will Vreceive and shield the shoulder `I3 formed at the junction of the screw-threaded portion Il of the handle `part l with the remainder ofthe latter. AThis is clearly shown in Figure 2.

The :thrust rod A'i is of such length that when the handle part 4 is screwed fully into the handle part 3, the upper rounded extremity il of the rod `will project into the gap 6 in the gripping head l `(asindica-ted in Figure '2), while `when the handle part 4 is unscrewed to some extent, the extremity 8 lof the rod will be withdrawn into the bore 5 '(as indicated in Figure 1).

The outer surfaces of the two handle parts 3 and 4 are lmilled or otherwise roughened as indicated at I4 and I5-'in Figure2 `to facilitate a gripbeing obtained `thereon `with the lingers `both in shaving and for screwing `one part `relatively to the other.

"With the `arrangement described and the parts inthe position `depicted by Figure 1, the gap E in .thegripping head will be `free from obstruc tionsoethat the `rear portion of the razor blade lr6 (Figure 2) can readily be engaged in the said gap. If the front opening of the gap 6 is wide enough., this engagement can beeiected bypushciently wide for this purpose, the engagement can be effected by slipping the blade in endwise. If, now, the lower handle part 4 is screwed into the upper handle part 3, the rounded end 8 of the thrust rod I will be moved into the gap 5 in the gripping head I so as to engage with the undersurface of the blade I6 and press the upper surface of the blade against the upper limb of the gripping head7 the result being that the blade will be held firmly but detachably in position.

The lower end of the thrust rod I may fit in the recess 9 with a detachable nt and both extremities of the rod may be rounded so that.

it is reversible.

The embodiment illustrated in Figure 3 is in many respects similar to that illustrated in Figures 1 and 2, and like reference numerals indicate like parts. In this case, however, the thrust rod 'I is shorter than before and takes the form of a plunger the lower end of which is provided with a flange I'I fitting freely in an enlargement I8 of the bore 5. The enlargement I8 provides accommodation for a compression spring I9 the upper end of which bears against the iiange, while the lower end fits in the recess 9 in the screw-threaded portion II of the lower handle part 4.

With this arrangement and with the lower handle part 4 fully screwed into the upper handle part 3, the plunger 'I is constantly urged upwardly under the influence of the spring I9 so that the upper rounded extremity 8 of the plunger always projects into the gap 6 of the gripping head, the degree of such projection being limited by engagement of the flange I'I with the upper end 20 of the enlargement I8. Provided the degree of proiection is not too pronounced, the rear portion of the razor blade I 6 can be engaged in the gap 6 of the gripping head I by a simple sliding action` while the two handle parts 3 and 4 remain fully screwed together, this being permitted by the cam action exerted by the blade on the rounded extremity 8 of the resiliently mounted plunger 'I. Should, however, the degree of projection be too great for this to be done conveniently. it merelv becomes necessary to unscrew the handle part 4 to some extent so as to relieve the pressure of the spring I9 on the plunger 7. In either case. with the handle part l fullv screwed home` the pressure of the spring I9 acting through the plunger 'I will be suicient to press the upper .surface of the blade I i5 into firm engagement with the upper limb of the grinning head I. so holding the blade in correct position for shaving.

In the embodiment -i'ust described the pressure of the spring I9 on the plunger 'I varies according to the extent to which the lower handle part 4 is screwed into the upper handle part 3. In the embodiment illustrated in Figure 4 a springpressed plunger 'I is also used, but in this case the pressure of the spring I9 on the plunger is constant, that is to say, the magnitude of its pressure in the plunger does not depend upon the position of the two handle parts 3 and 4 relatively to each other. To this end, the plunger not only extends through the bore 5 in the upper handle part 3, but is lengthened to extend with a sliding iit, through a bore 2| in the lower handle part 4. The bore 2l opens into a cavity 22 of enlarged diameter which freely accommodates the flange I 'I at the lower end of the plunger and which extends to the base of the lower handle part 4. The cavity 22 is screwthreaded to receive a screw-threaded plug 23.

and the space between this plug and the flangel I'I accommodates the compression spring I9 which maintains the flange I1 normally in engagement with the shoulder 24 formed between the bore 2I and the cavity 22, the plunger being of such length that, under these conditions, its upper rounded end 8 projects into the gap 6 in the gripping head I when the razor blade is absent.

When the blade is in the process of being inserted in the gap 6 of the gripping head I, the pressure of the blade on the exposed rounded headv 3 of the plunger 'l' will cause depression of the plunger against the resistance of the spring I9, whereupon the spring will react to press the upper surface of the blade into contact with the upper limb of the gripping jaw, the blade thereby being held firmly but detachably in position in the gripping jaw.

Should the degree of projection of the upper end of the plunger 'I into the grip 5 be too great for the blade to be readily inserted, it can be reduced by unscrewing the lower handle part 4 from the upper handle part 3 so as to cause withdrawal of the upper end of the plunger to the requisite extent, the two handle parts can thereupon be fully screwed together, the spring I9 allowing the plunger I to accommodate itself to the thickness of the blade. The possibility presents itself of varying the pressure of the spring I9 by adjusting the plug 23.

The construction illustrated in Figure 4 allows the two handle parts 3 and 4 to be entirely separated from each other while leaving the plunger 'I and the spring I9 in situ with the lower handle part 4.

Although in the various embodiments illustrated the gripping head is shown made integrally with the upper handle part 3, it will be understood that it can, if desired, be made as a separate member secured to the said part.

What I claim and desire to secure by Letters Patent of the United States is:

1. A safety razor blade holder for a blade with a single cutting edge, the said holder comprising a handle divided into two parts, namely an upper part and a lower part. the said two parts having screw-threaded engagement with each other. a grinning head made inteirrallv with the Isaid upper handle part, the said head including a non-resilient jaw overhanging the upper handle part so as to provide between it and the fatter a recess adapted to accommodate the portion of the blade opposite the cutting edge, a hole extending through the upper handle part from the said recess. a rod accommodated in the said hole and having its lower end operatively connected to the lower handle part, the said rod being movable in the said hole so that by rotation. of the lower handle part relatively to the upper handle part the upper end of the rod will proiect into the said recess and, when the blade is in position in the recess, will engage directly with the under-surface of the blade so as to press the upper surface of the blade against the said overhanging jaw, thereby retaining the blade in the said gripping head, the lower handle part being provided with a recess, and a spring accommodated therein in direct contact with said rod.

2. A safety razor blade holder according to claim 1, wherein the said rod is in direct engagement with the lower handle part.

3. A safety razor blade holder in accordance with claim l, wherein the lower end of the upper fhennfdle part is also provided with a recess, the recess of the lower handle part being at the upper enthereof and complementary to the recess of the Iupper handle part, a part of the spring being 'c'commodated in each recess.

EDGAR HAROLD LAW.

REFERENCES CITED 'fae of this patent:

UNITED STATES PATENTS Number Name Date Muller Nov. 22, 1904 Greenbrier Jan. 22, 1918 Salemi Mar. 1'7, 1925 Brown Apr. 21, 1936 Grner June 10, 1941

On peut donc en déduire que nos modèles datent tous des années 40 à 50.

Page 1 sur 2 • 1, 2

Permission de ce forum:

Vous ne pouvez pas répondre aux sujets dans ce forum